The Thermal-Link (DC-ATCO)-DC Alloy Type is installed on the heater and connected

in series with the high-voltage heating circuit. When the heater is abnormally heated,

the temperature reaches the melting point of the Thermal-Link, which can cut off the

450 VDC circuit, and the heater stops working. The ceramic housing can withstand

500 ℃ temperature impact for a short time.

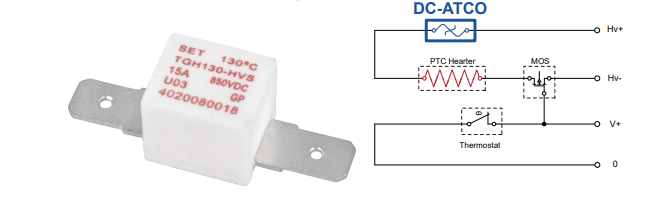

The Thermal-Link (DC-ATCO)-DC Alloy Type is installed on the side of the PTC heater.

Under normal conditions, the Thermal-Link remains connected. When the IGBT/MOS

breakdown, short circuit or other abnormality occurs, the heater continues to heat up,

the temperature exceeds the set value and reaches the melting point of the

Thermal-Link, the circuit is cut off and the heater stops working.

The Thermal-Link (DC-ATCO)-DC Alloy Type is installed on the side of the heating tube

and connected in series with the DC heating circuit. During the failure process of the

defroster, the temperature reaches the melting point of the Thermal-Link, the circuit is

cut off, and the heater stops working.

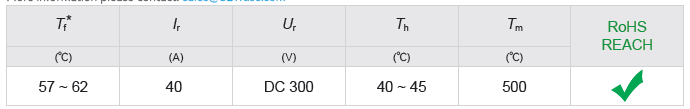

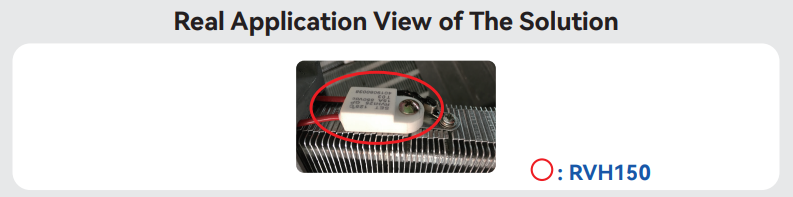

The Alloy Thermal-Link (ATCO) is installed between the heat sinks. During the fault

process, the temperature reaches the melting point of the Thermal-Link, which

physically cuts off the circuit to protect the equipment.

The speed regulating resistor is connected in series with the Organic Thermal-Link.

When the thermal element of Organic Thermal-Link senses the abnormal heat and

reaches its predetermined melting temperature, the thermal element strength

decreases due to melting, and the trip spring will separate the sliding contact, then

disconnect the circuit.

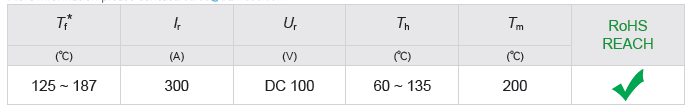

The DC-Alloy Thermal-Link (DC-ATCO) is used as the electrical connection at the cell

parallel point. When an over current occurs, the Thermal-Link can heat itself and fuse.

It meets the requirements of UN38.3 lithium batteries transportation. In the event of

partial overheating, the heat is transferred to DC-Alloy Thermal-Link(DC-ATCO), the

connection point can be passively cut off.

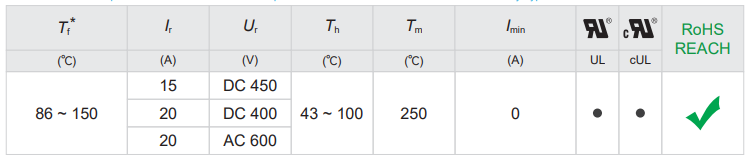

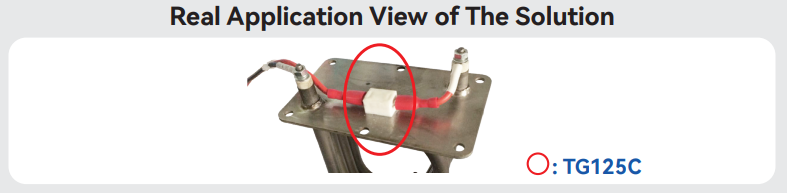

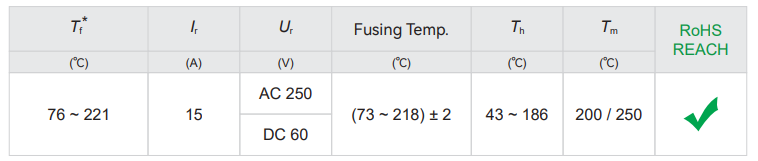

This special DC-Alloy Thermal-Link(DC-ATCO) has separated the temperature sensing

part and the current carrying part, which reduces the temperature rise difference

between current carrying part under different currents and ensures the operating

temperature accuracy of temperature sensing part. It is installed in the charging /

discharging circuit, close tight to the battery, and cut off the circuit when an

abnormal temperature rise of the battery occurs.